Business response to environmental challenges: three cases of Russian industrial companies

Introduction – Comparison with previous studies

|

Previous studies on business response to environmental challenges are primarily focused on companies that… |

The present study is focused on the cases of companies that… |

|

…come from developed economies |

…come from Russia |

|

…operate in international market, are industry leaders |

…have a varying scale of operations (global / national / regional) |

|

…adopt proactive environmental policies |

…display varying levels of environmental responsibility |

Introduction – Why cases?

Case analysis will help to understand the following issues of environmental policies of companies from emerging economies:

- Development of relationship between business goals and environment protection goals inside the companies

- Problems the companies face while developing environmental policies

- The companies’ view on the role of the government in environmental responsibility development

Cases Introduction

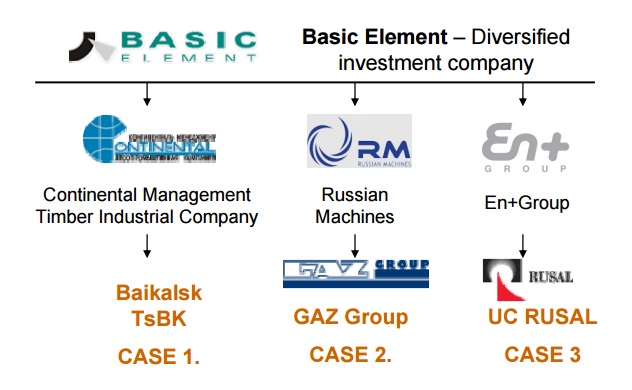

The study is focused on analysis of three Russian companies, controlled by one holding company

Cases Introduction – Companies Review

|

|

Baikalsk TsBK |

GAZ Group |

UC RUSAL |

|

Industry |

pulp and paper production |

vehicle production |

alumina and aluminum production |

|

Scale |

regional |

national |

global |

|

Environmental responsibility |

traditional |

preventive- strategic |

strategicsustainable |

Cases Introduction – Sources of Information

- Interviews with companies’ representatives

- Companies’ internal documents

- Publicly available sources (companies’ published reports, mass media)

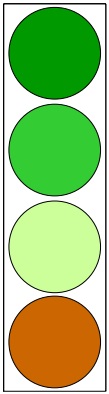

Cases Introduction – “Traffic lights” Approach

“Traffic lights” – our visual presentation of the classification of environmental responsibility levels as described by Robbins (2001)*

Dark green - Sustainable: Company aims to be an “environmental leader” and solve global and national environmental problems

Green - Strategic: Environmental policy is a part of overall corporate strategy and helps to find new possibilities (positive image, new niches)

Light green - Preventive: Environmental policy is aimed at preventing possible ecological risks and enabling resources and energy saving

Brown - Traditional (compliance): Environmental policy is concentrated on meeting requirements and emissions treatment at the end of pipe

* Robbins, P.T. 2001. Greening the corporation. Management strategy and the environmental challenge. London: Earthscan Publications Ltd.

Case 1. Baikalsk pulp and paper mill (Baikalsk TsBK): From environmental to humanitarian disaster

Baikalsk TsBK: Company Profile

- One of the leading enterprises of the Irkutsk region of the RF (East Siberia)

- Products – pulp, wrapping paper and ancillary products

- Main markets – China (pulp), Russia (defense industry)

- Private and public ownership

51% – Continental Management

49% – Russian Government

- Main stakeholder of a town of Baikalsk

2300 employees (town population – 15000)

provider of heating for the whole town

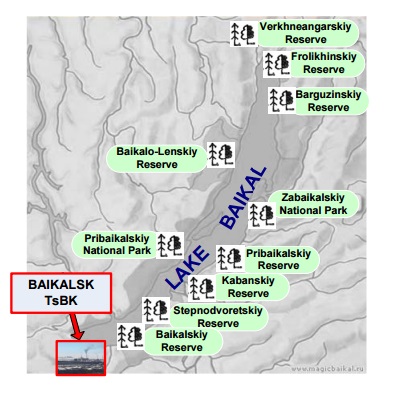

Baikalsk TsBK: Background of the Environmental Policy

In 1950s Baikalsk TsBK was placed on the waterside of the lake Baikal, as the production technology required a large volume of pure water

- Lake Baikal is the world deepest lake, surrounded by wildlife preservations

- Therefore, the plant was equipped with unique and advanced waste treatment facilities

- Nevertheless, from the very beginning the plant has been the target for accusations from environmentalists

Baikalsk TsBK: Background of the Environmental Policy

Experts’ estimations on the extent of Baikalsk TsBK negative impact on environment are controversial

Baikalsk TsBK certainly contributes to the total anthropogenic impact on Lake Baikal water area”. However, “the whole water of the Baikal Lake keeps pure” in spite of the presence of “the selected areas of insignificant local pollution”, including Baikalsk TsBK area

Government report “On the condition of Lake Baikal and measures for its protection in 2004”

Baikalsk TsBK’s negative impact on environment is insignificant and localized and does not tend to increase. Nevertheless, Baikalsk TsBK needs modernization, including adoption of re-circulated water supply system to eliminate the dumping of waste waters to Lake Baikal

United Nations Industrial Development Organization (UNIDO)

Baikalsk TsBK: Environmental Policy Development

In 2006 Baikalsk TsBK adopted the program to install the re-circulated water supply system to meet the requirements of state authorities, society and international experts

- Private stockholder invested $12,4 mln to install re-circulated water supply system

- The system started to operate on September 5, 2008

Launch of the re-circulated water supply system is “a very important event not only for Irkutsk region but for the whole Russia”

Y. Trutnev, Minister of natural resources and ecology of the RF

Baikalsk TsBK would be the one of the “few applicants to the certificate of the environmentally friendly enterprise of Russia”

V. Kirillov, Head of the Federal Supervision Service for nature management

Baikalsk TsBK: Environmental Policy Results

Environmental modernization made further operation of the enterprise impossible due to the following reasons:

- Technological process of production of the only profitable product – bleached pulp – is incompatible with re-circulated water system

- Output of unbleached pulp became unprofitable as its price fell by 30% after the economic crisis set in

|

Product |

Price, dollars per ton* |

Production cost, dollars per ton* |

|

Unbleached pulp |

350 |

500 |

|

Bleached pulp |

800 |

650-700 |

* Data as of the end of 2008

Elimination of environmental disaster resulted in humanitarian disaster:

- Shutdown and mass unemployment in the town

- Reduction of tax revenues for regional and municipal budgets

- Risk for town population to stay without heating

|

Stockholder |

Proposal |

Timeframe |

|

Private |

Revert to the open water supply system in order to give the enterprise an opportunity to introduce the new clean technology of pulp bleaching (other conversion opportunities are unprofitable) |

3-5 years |

|

Government |

Shut down the enterprise and develop the alternative employment opportunities or re-locate the population |

2-6 years |

Baikalsk TsBK: To be continued…

Baikalsk TsBK from the outset was trapped in the framework of the old traditional paradigm - environment protection was seen as additional cost, no new factors of environmental “profitability” were createdFurther questions:

- Which goals should be given precedence in the decision making process – environmental, business or social – if they cannot be integrated in a consistent set of policies due to their incompatibility?

- How can the interests of the owners, employees, government authorities, environmentalists and other stakeholders be balanced?

Case 2. GAZ Group. From lean production to environment protection

GAZ Group: Company Profile

- Leading vehicle producer in Russia - 18 enterprises in 10 regions

- Wide range of products – light commercial vehicles, trucks, roadmaking and construction machines, engines, buses, automobiles and components

- One of the global leaders in LCV and bus production – ranked among world Top-20 LCV producers, world Top-10 bus producers

- Main market – Russian Federation

GAZ Group: Background of Environmental Policy

In November 2002 GAZ Group adopted an environmental policy to meet governmental standards and to improve company’s image before international stock offeringAmong the main driving forces were the opportunity to decrease environmental payments and tightening of government standards and regulations

Alexander Lukichev

GAZ Group’s approach to environmental policy was based on step-by-step improvements in accordance with the overall ideology of “lean manufacturing” introduced at the Group’s enterprises

“Lean manufacturing” is a set of techniques aimed to optimize production process and get rid of excessive costs

Monden, Y. 2007. Toyota Management System.

Moscow: Institute for Complex Strategic Studies

GAZ Group: Environmental Policy Development - 1

GAZ Group’s environmental policy was focused on preventive measures and quick cost reduction – environmental measures were entwined with production process optimization- Emissions and wastes were reduced due to improvement of production management and technological processes

Example: Introduction of new painting system resulted in decrease in waste water volumes by 500 thousand m 3 per year and air pollution emissions by 70,5 tons per year

- Waste management was improved and recycling was introduced to get rid of excessive costs

Example: Wastes are collected separately by types in the marked boxes. A special company “GAZVtorResurs” which treats these wastes provides discounts for collecting recyclable waste.

GAZ Group: Environmental Policy Development - 2

Promotion of the principles of environmental responsibility across the Group’s enterprises was also based on “lean manufacturing” ideology: roll-out of best practice from pilot to other sites and employee involvement- Environmental policies were expanded through the “chain reaction” – from a pilot production site to other departments and enterprises

Example: In 2008 the pilot project on energy saving at JSC “Tver Excavator Plant” allowed the plant to cut energy consumption by 10%, thus saving over $615.000. Today energy saving is practiced by all the Group’s enterprises.

- Environmental changes were introduced through extensive employee involvement

Example: Introduction of environmental policies was accompanied by educational programs, competitions between enterprises, and top management initiatives to adopt principles of personal responsibility for environment protection.

GAZ Group: Environmental Policy Results

GAZ Group managed to improve its operational efficiency through resource saving and to develop the image of the environmentally responsible company. Today GAZ Group considers environmental safety of production as integral part of business strategy.In 2008 GAZ Group was awarded the gold medal at the “Gold Medal “European Quality” contest in the nomination “100 Best Russian Companies. Environment and Environmental Management”

Further questions:

- Will the company’s environmental initiatives be supported by the government?

- Will the company be able to develop its environmental responsibility further without government support?

Case 3. UC RUSAL. From local to global environmental activities

The United Company RUSAL: Company Profile

- The global industry leader – 12% of the global output of primary aluminum, 15% of the global alumina production

- Global scope of operations – in 19 countries on 5 continents

Russia – 12 regions (mostly aluminum smelters)

- The complete production chain - bauxite and nepheline ore mines, alumina refineries, aluminum smelters, casthouse business for production of alloys, foil mills and production of packaging materials, power-generating assets

UC RUSAL: Background of Environmental Policy

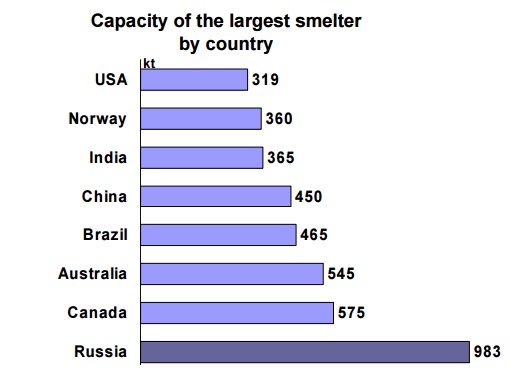

Till the end of 1990s Russian enterprises which currently comprise RUSAL followed the traditional paradigm – environmental costs were borne in order to comply with standards and to avoid public dissatisfactionMost Russian aluminum smelters are…

- Very large (Bratsk and Krasnoyarsk plants are the largest aluminum smelters in the world)

- Situated very close to the cities

- Constructed in 1960ies when environment was of marginal importance

The activities of aluminum plants in Russia were always watched over very carefully by society and by supervision authority as well

Ivan Rebrik

UC RUSAL: Environmental Policy Development

UC RUSAL’s approach to environmental policy was complex and based on total technological modernization to prevent the negative environmental impactIn the beginning of 2000s the environmental safety started to be treated as essential for business survival

Ivan Rebrik

- The whole production facilities were modernized

Example: Sayanogorsk and Krasnoyarsk smelters in 2003-2004

- New plants were constructed in compliance with high environmental standards

Example: Khakas smelter launched in 2006 New plants were constructed in compliance with high environmental

UC RUSAL’s technological modernization not only allowed prevent the company’s negative impact on nature, but also helped to reduce costs due to resource saving- Modernization of existent technologies and development of the new ones allows company to reduce energy and other resource consumption

Example: Modernization of Soderberg technology allowed to increase productivity of the potline, to reduce hazardous emissions by 15-20% and to increase energy efficiency by 20%

Example: The Engineering and Technological Center of RUSAL, was founded in 2002 to develop more productive and energy efficient technologies

Other ways to save resources and protect environment- Secondary aluminum production development

|

Resource consumption per 1 ton of secondary aluminum production as compared with 1 ton of primary aluminum production |

Energy |

Bauxite |

Chemical reagents |

|

20 times less |

8 tons less |

4 tons less |

- Introduction of the re-circulated water supply system

Example: 55% of UC RUSAL plants were using re-circulated supply system by the end 2007

- Recycling wastes, utilizing hazardous wastes

UC RUSAL: Reducing Risks of Climate Change

Modernization of production facilities and resource saving made environmental protection a vital part of the company’s strategy and motivated it to adopt challenging goals of sustainable developmentIn 2007 UC RUSAL announced its Climate goal:

- To reduce the direct GHG emissions by 50% by 2015 and to eliminate carbon emissions in the long term perspective

Translating Climate goal into policies:

- Developing company’s GHG emissions management

- Utilizing environmentally-friendly power sources (hydro and nuclear)

UC RUSAL: Other Environmental Activities

- Employee environmental education

Informing employees about the consequences of environmental rules’ violation, providing educational programs for different employee and partner categories (senior management, workers, contractors etc.), involving employees into environmental activities

It is the people who really implement the environmental policy

Ivan Rebrik

- Community involvement

Example: “Environmental information centers” of UC RUSAL give the access to the information on company’s environmental policy and serve the community by providing environmental education to citizens.

- Rehabilitation of environment

Example: Development of a unique monitoring system for populations of rare and endangered flora and fauna in Altai-Sayan region within the impact zone of the Sayanogorsk Aluminium Smelter.

UC RUSAL: Environmental Policy Results

The company which started with complying to environmental standards imposed by authorities and communities, evolved into an environmentallyresponsible business which provides the efficiency of its green investments through cost reduction, image improvement, and gaining competitive advantage in GHG emissions’ management in RussiaRussian business has moved to a new stage of development, giving special attention to the planet’s safe future

Marco Borsotti,

UN Resident Coordinator and UNDP Resident Representative in the RF

Further questions:

- Will the company’s profit and environmental goals be compatible under the current conditions of aluminum price decrease?

- Can the company’s best practice be transferred to other companies – and how?

- Do other companies in Russia have the sufficient resources to make the same transition from traditional to sustainable environmental approach?

Conclusion - Barriers on Way to Environment Responsibility

- Limited time – government and environmentalists’ requirements often require rapid action without regard of the companies’ possibilities and resources

The key problem is that we are too often in a hurry

Ivan Rebrik

- Lack of environmentalists with a business perspective – and lack of managers / employees with the environmental consciousness

We need to shift environmentalists’ mindset to business approach

Nikolay Sakharov

- Limited investment sources

It would have given business considerable support if government allowed companies to use environmental payments

Alexander Lukichev

Conclusion - Policy Implications

Environmental policy of the Russian government still follows the old “end of pipe” paradigm with an emphasis on environmental payments and penaltiesNew incentives for companies are necessary:

Additional investment sources- Tax relieves for corporate environmental activities

- Permission to invest environmental payments in company’s environment activity

- R&D subsidies

- Subsidized

- Environmental education for businessmen

- Business education for environmentalists

- Setting clear ”rules of game” – clear timeframe of new environmental standards

- Facilitating information sharing through best practices promotion